中国工信部高精度传感器一条龙应用计划示范项目,24H热线电话:18988775266

国家级专精特新“小巨人”企业,国家级高新技术企业! (ENGLISH英文站)

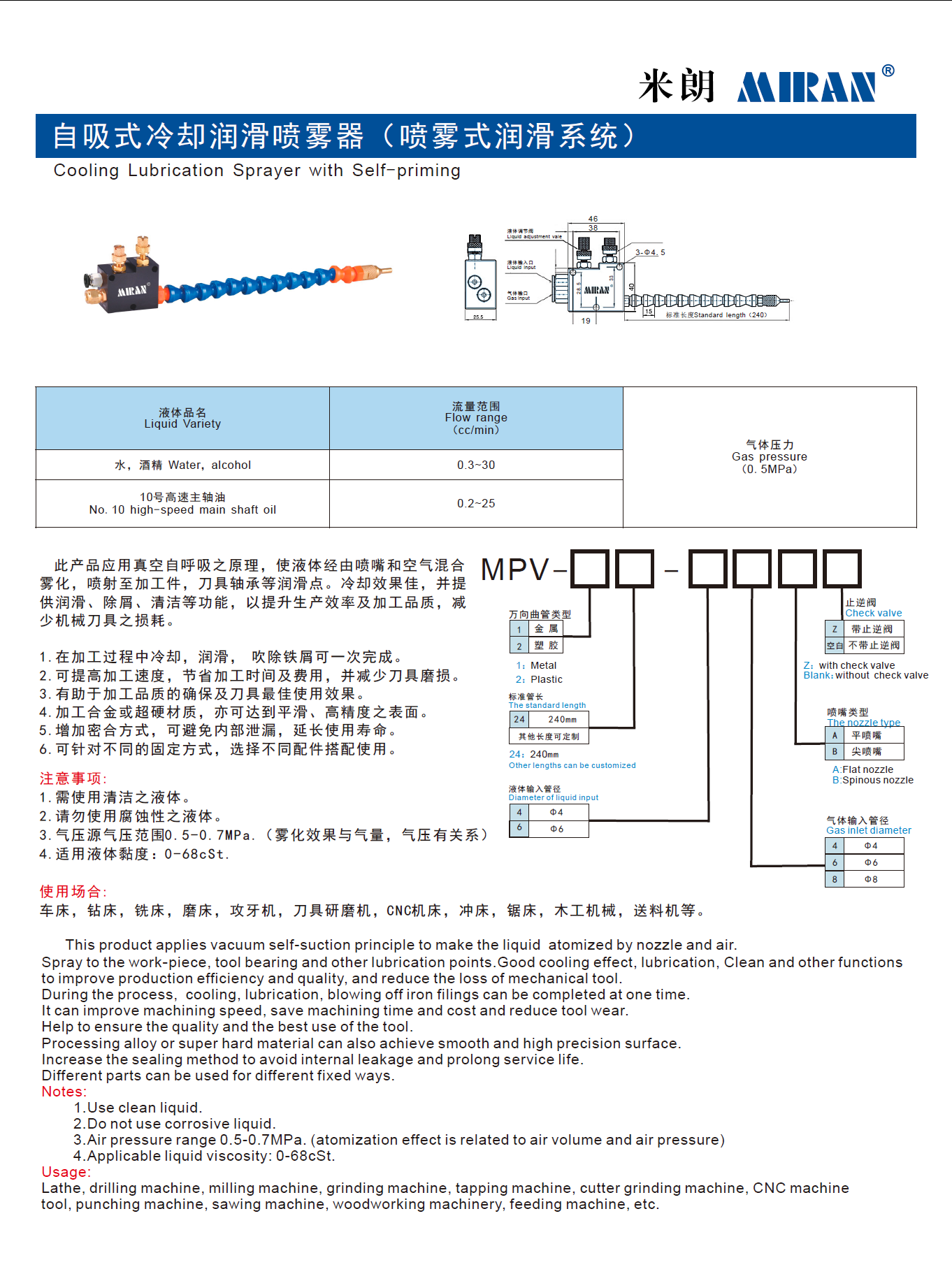

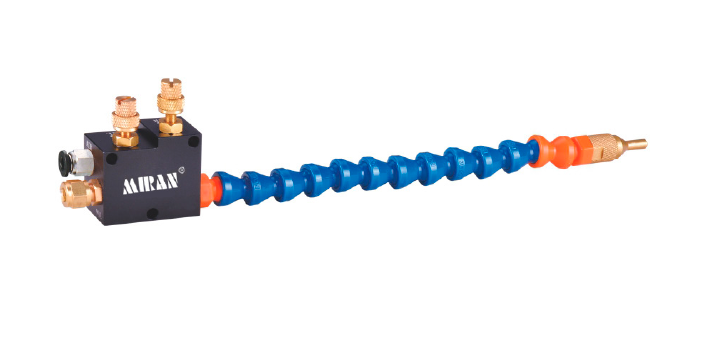

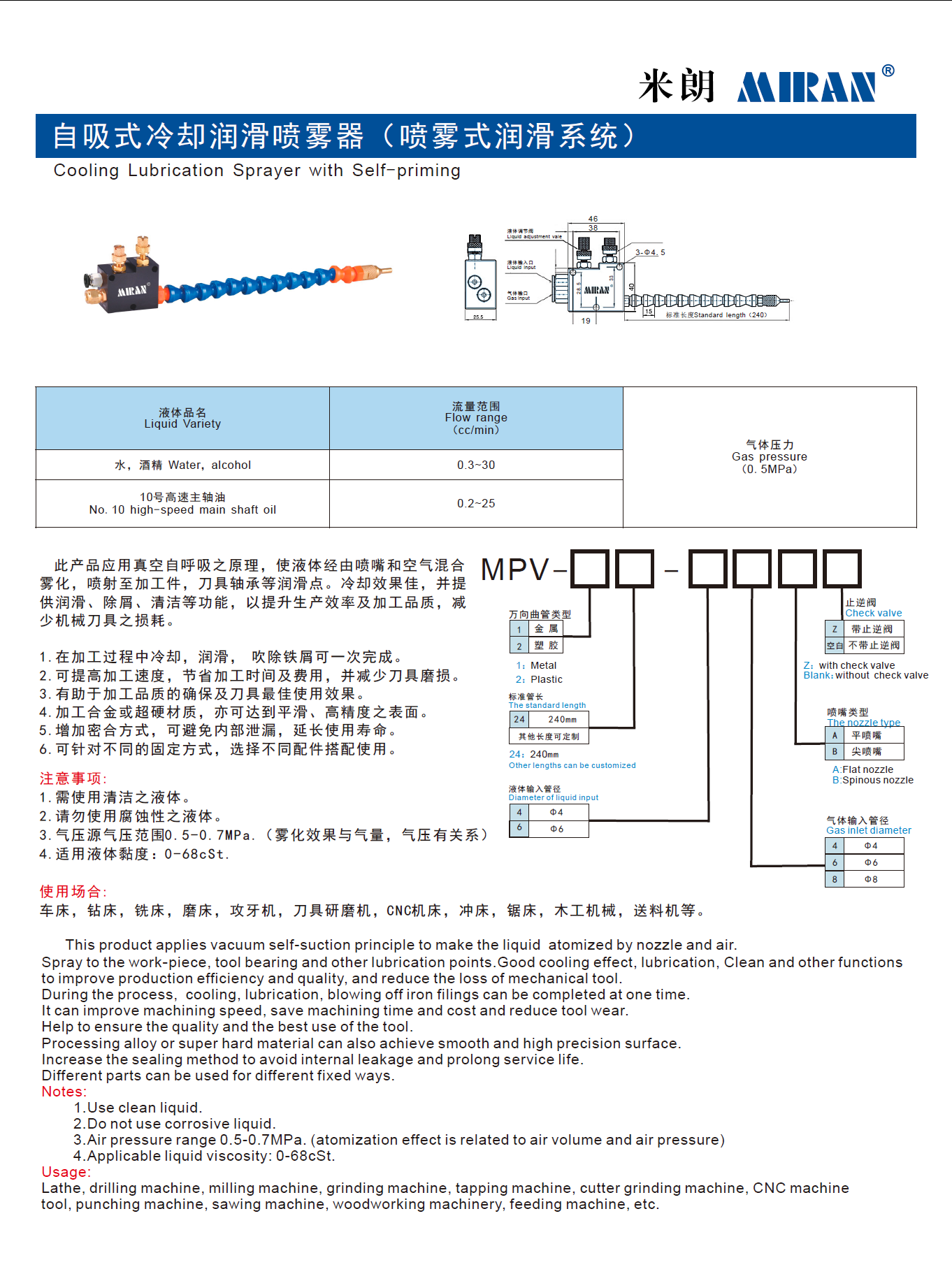

自吸式冷却润滑喷雾器(喷雾式润滑系统)Product introduction

您现在的位置:首 页 > 产品展示 > 产品详情

此产品应用真空自呼吸之原理,使液体经由喷嘴和空气混合雾化,喷射至加工件,刀具轴承等润滑点。冷却效果佳,并提供润滑、除屑、清洁等功能,以提升生产效率及加工品质,减少机械刀具之损耗。

1 .在加工过程中冷却,润滑, 吹除铁屑可一次完成。

2 .可提高加工速度,节省加工时间及费用,并减少刀具磨损。

3 .有助于加工品质的确保及刀具最佳使用效果。

4 .加工合金或超硬材质,亦可达到平滑、高精度之表面。

5 .增加密合方式,可避免内部泄漏,延长使用寿命。

6 .可针对不同的固定方式,选择不同配件搭配使用。

注意事项:

1 .需使用清洁之液体。

2 .请勿使用腐蚀性之液体。

3 .气压源气压范围0 . 5 - 0 . 7 M P a .(雾化效果与气量,气压有关系)

4 .适用液体黏度:0 - 6 8 c S t .

使用场合:

车床,钻床,铣床,磨床,攻牙机,刀具研磨机,C N C机床,冲床,锯床,木工机械,送料机等。

This product applies vacuum self-suction principle to make the liquid atomized by nozzle and air.Spray to the work-piece, tool bearing and other lubrication points.Good cooling effect, lubrication, Clean and other functions to improve production efficiency and quality, and reduce the loss of mechanical tool.

1、During the process, cooling, lubrication, blowing off iron filings can be completed at one time.

2、It can improve machining speed, save machining time and cost and reduce tool wear.

3、Help to ensure the quality and the best use of the tool.

4、Processing alloy or super hard material can also achieve smooth and high precision surface.

5、Increase the sealing method to avoid internal leakage and prolong service life.

6、Different parts can be used for different fixed ways.

Notes:

1.Use clean liquid.

2.Do not use corrosive liquid.

3.Air pressure range 0.5-0.7MPa. (atomization effect is related to air volume and air pressure)

4.Applicable liquid viscosity: 0-68cSt.

Usage:

Lathe, drilling machine, milling machine, grinding machine, tapping machine, cutter grinding machine, CNC machine tool, punching machine, sawing machine, woodworking machinery, feeding machine, etc.